What is a chiller?

A blast chiller is a device that quickly lowers the temperature of food. Blast chillers are also known as blast freezers or blast freezers. They usually have several shelves where food trays or sheet trays can be stored and cooled to extremely low temperatures.

How does a chiller work?

Blast chillers work by applying pressurised cooled air to the food placed inside. This rapid cooling process (blast chilling) decreases the size of ice crystals that appear on the food. When de-icing food, the large ice crystals melt and cause excess moisture to be released, which affects taste and quality.

- AISI-304 stainless steel exterior, except for the backrest and base

- AISI-304 stainless steel interior

- Doors with automatic closing system and magnetic seal (stays open beyond 90° of opening)

- Inductive door opening micro switch

- AISI-304 stainless steel worktop

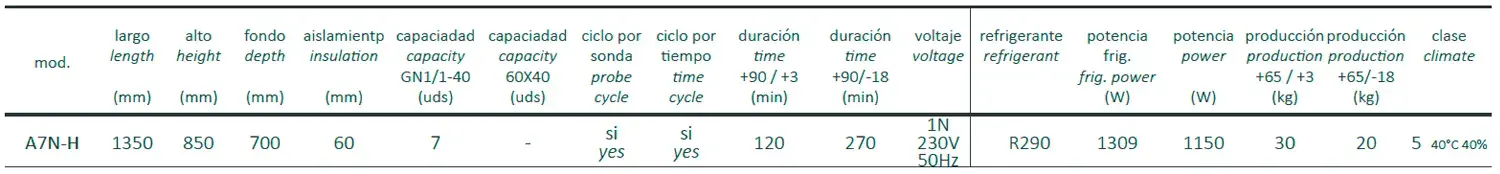

- Combined inner capacity GN1/1 (trays or trays not included)

- Ventilated condensing unit

- Forced draught system evaporator, with anti-corrosion epoxy coating

- Expansion valve

- Injected polyurethane insulation, density 40 kg/m³.

- Graphical control panel with 5-inch TFT touch screen, IP65

- Advanced function management for state-of-the-art blast chillers.

- RS-485 and USB connectivity

- Detachable, heated, detachable spike probe included

- Cycle management by time or temperature

- Test of correct probe insertion (temperature management)

- Recording of HACCP data, viewable on screen or downloadable via USB port in CSV format.

- Hard/soft" blast chilling and freezing cycles

- 4 combinations of standard folding cycles

- Continuous cycle programming by temperature or time

- Multiple customisable programmes

- Temperature-optimised resistance defrost at cycle start, temperature optimised

- Efficient management of energy consumption

- Optional: WIFI interface allows viewing of alarms, machine status, HACCP history and access to configuration operations from PC, smartphone or tablet