Developments in meat maturation

Welcome to the Coreco blog. Today we would like to give you a brief history of the evolution of meat maturation. This article will try to give an overview of the origins, evolution and current techniques of maturation, inviting you to discover how this ancient practice has become one of the most valued in today's gastronomy.

Tradition of dry maturing

In Europe, dry maturation of beef has a long tradition, especially in countries such as Germany, where it is known as 'Reifung' or 'Trocknung'. In France, dry-aged meat is known as 'viande maturée' and in Italy as 'carne stagionata'.

However, in the United States, dry aging of beef was developed in the early 20th century, first as a method of preservation and then as a way to improve the quality and flavour of the meat. American butchers and chefs continue to experiment with different dry-ageing techniques in order to achieve a meat with better organoleptic characteristics.

Dry-aged beef has become increasingly popular in recent decades. More and more restaurants and steakhouses offer their customers various types of cuts between 30 and 240 days, or even longer.

Those who enjoy this preparation are increasingly turning to this type of meat, which has also led supermarkets and butchers to offer it as an option to buy and prepare at home.

History of dry-matured beef

The maturation of beef is not a contemporary practice as it may seem. As far back as the Middle Ages, it was done to improve tenderness and flavour. In the 19th century, French chefs and gourmets such as Antonin Carême practised dry maturation, known as 'mortification', by leaving the meat at room temperature for days or weeks until the surface was corrupted. Carême recommended keeping it "as far away as possible" (McGee, 2007).

At the end of the 19th century, Charles Tellier developed refrigerated cabinets. He installed them on a ship and transported beef from Rouen to Buenos Aires, preserved between -2 and 0°C for 105 days. The meat arrived in perfect condition, marking a milestone in beef maturation.

Some 50 years ago, dry ripening was replaced by vacuum packing, due to its efficiency in processing and storage (Dashdorj et al. 2016). However, it fell into disuse in the 1960s and was revived in the 1990s.

According to Richard H. Turner in his 2017 book "Prime Flesh". considers the evolution of meat maturation as a fundamental process to improve the quality and flavour of the meat. He also explains that the meat of calves with more developed muscle mass is more tender than that of ordinary calves in shorter maturation times.

Turner also includes in his book a criticism of intensive livestock farming because it results in less flavourful meat, although many farmers are driven to this type of production.

Technological advances in maturation

In recent decades, advances in refrigeration technology have been made to help make the rigorous ageing process safe and stable enough to create suitable maturation climates. Temperature, humidity and airflow must be monitored and controlled at specific temperatures in order for the meat to be processed. With dry maturation chambers, restaurants, shops and butchers can mature beef safely and naturally.

Coreco's contribution to meat maturation in chillers

Coreco has developed and patented the 'Master Ageing Controller', an advanced system that ensures precise control of all critical parameters during the meat ageing process.

This device allows for more accurate monitoring of temperature, humidity and airflow, ensuring an optimal maturation environment. Thanks to this technology, moisture loss is reduced, tenderness is improved and flavours are intensified, allowing meat professionals to offer quality products to their customers.

If you need more information or want to know more in depth, please do not hesitate to contact us by following this link linkWe will be delighted to help you and answer any questions you may have.

Ageing as a conservation technique

Ageing is the controlled decomposition of meat used as another form of meat preservation. Without refrigeration, hunters and farmers stored cuts of animal flesh in cold, dark cellars or caves, where moulds, microbes and enzymes were responsible for tenderising and preserving it.

Undoubtedly, one advantage of the preservation process was the tendency of the meat to become more flavoursome and tender with age. Like cheese, early matured meats were naturally inoculated with strains of penicillium mould and other microbes that create the umami flavour so prized today.

Deterioration management

The ageing process begins the instant an animal dies. Enzymes in muscle tissue begin to digest long chains of glucose molecules called glycogen. Enzymatic digestion creates lactic acid within the muscle, which maintains a low pH level inhospitable to harmful bacteria and microbes.

However, when an animal is stressed just before it dies, its body uses up excess glycogen stored in the muscles. This leaves nothing for enzymes to digest, creating an environment within the tissue that could allow bacterial growth.

Rigor mortis appears between one and four hours after death, depending on the size of the animal. Hanging an animal before rigor appears allows the muscles to remain stretched rather than bunching into a tight ball that will be difficult to cut and unpleasant to eat.

Approximately 48 hours after the onset of rigor, enzymes called calpain and cathepsins begin to break down the proteins that bind the muscle filaments together and dismantle the connective tissues, which causes rigor to cease.

The science of taste and tenderness

As the ageing process progresses, enzymes inside the muscles create molecules that increase the flavour and tenderness of the meat. Proteins are broken down into amino acids, such as glutamate (also present in monosodium glutamate), which we recognise as savoury or umami.

Glycogen is broken down into glucose molecules, which are the sugars that create the caramelised browning in seared meat, also known as the Maillard reaction. Fats are transformed into aromatic fatty acids.

The length of time a piece of meat can be aged depends on the type and amount of fat present in the animal. More fat will allow longer ageing due to slower moisture loss and a greater protective barrier around the meat.

Minimising exposure to oxygen and light is key to avoiding fat rancidity, especially in animals with unsaturated fat, such as pork and fish.

Ageing well

During the dry ageing process, humidity, temperature and air circulation can be decisive for the final product; it is important that there is sufficient space between the parts to allow the necessary air circulation.

The ideal environment for dry maturation is a temperature between 1.5° and 3°C and a humidity of 50 % to 60 %. Ideally, the meat should have a thin outer rind to protect it and allow continued enzymatic activity while allowing water to escape. This, in turn, concentrates flavours in the meat and reduces the possibility of bacterial overgrowth.

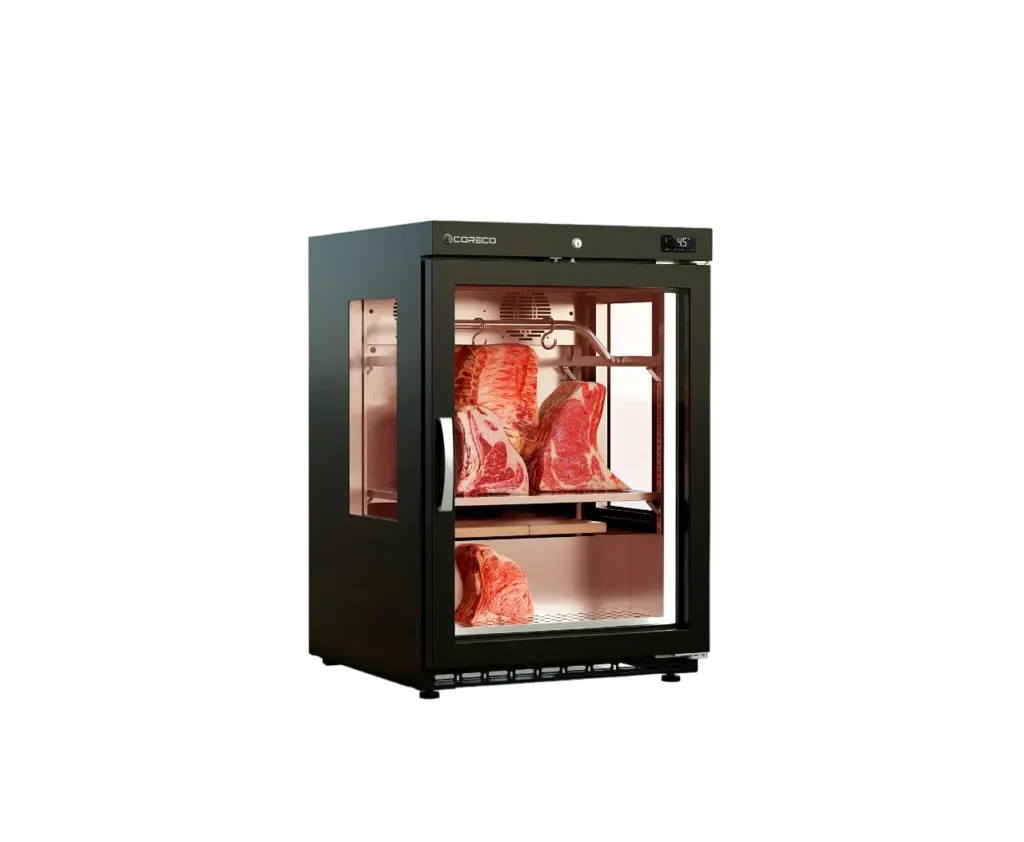

Maturation technology in refrigerator

Currently, the most common way to carry out this process is in a meat maturation cabinet. Its operation is very simple, consisting of leaving the meat to rest inside, which is subjected to a constant flow of air, humidity and temperature, creating a controlled environment that prevents the appearance of fungi and bacteria.

Proper ageing removes moisture from meat and allows moulds such as penicillium to grow. Penicillium moulds are the basis of antibiotics, which means that a spore coating on meat not only adds flavour, but also protects against harmful bacteria.

To age or not to age

So why do we pay so much for one of the oldest foods known to mankind? Dry-aged meat is a labour that needs a lot of care and control for those who want to do it right, and it takes time.

Perfectly matured pieces of meat start with correct cutting and chilling from the moment the animal dies in the slaughterhouse. A badly cut carcass or a poorly managed chiller can destroy the ageing prospects of even the most perfectly marbled beef.

Aged meat also loses weight as it ages, concentrating the cost of that steak into a smaller and smaller package the longer it sits in the refrigerated cabinet. These care and control intensive processes undoubtedly create something tastier, more tender and more valuable than unaged meat.

Cultural and gastronomic developments of meat maturation

Meat maturation has not only been a technical process, but also a cultural phenomenon. In ancient times, matured meat was considered a luxury reserved for the upper classes due to the complexity and time required for its preparation. Over time, this technique has been adopted and improved by various cultures, each with their own unique touch.

Today, dry-aged meat has become a key element in haute cuisine menus, reflecting a growing appreciation for the complex flavours and textures that can only be achieved through this process.

Impact on modern gastronomy

Today, many nationally and world-renowned chefs in high-end restaurants incorporate dry-aged meat into their menus. This process, as we have seen, not only enhances the flavour of the meat, but also allows chefs to experiment with new flavour combinations and preparation techniques.

The Dry Aged maturation process is the preferred process when it comes to meat, as well as the different cooking points, and this is encouraging more and more restaurants to purchase maturation cellars.

The enhanced texture and greater concentration of flavours make dry-aged meat an attractive option for both experienced diners and those seeking an exceptional dining experience. Restaurants that incorporate Dry Aged maturation often feature it on their menu to highlight the unique characteristics of premium meat.

Scientific and technological aspects

Technology has played an important role in the evolution of meat maturation. Advances in the regulation of temperature, humidity and air flow have allowed precise control of the process, improving both safety and quality of the final product.

Coreco's 'Master Ageing Controller' is an example of how technological innovation can optimise every stage of meat ageing, ensuring consistent, high quality results.

Frequently asked questions on meat maturation development

Dry maturation of meat dates back hundreds of years. At that time, cuts of meat were hung in cool, dark environments to preserve them and enhance their flavour and tenderness. This technique, known as "hanging" the meat, was the forerunner of modern dry maturation.

With advances in vacuum-packing technology in the 1960s, wet maturation replaced dry maturation. This method was faster and more cost-effective because it allowed more water weight to be retained, although it did not offer the same depth of flavour and tenderness as dry ripening.

Before the invention of refrigeration, meat maturation faced significant challenges due to unstable temperatures, which could result in contamination with dangerous bacteria. Meat was stored in cellars or caves, which did not always guarantee a safe and controlled environment.

With the invention of refrigeration and advances in temperature, humidity and airflow control technology, meat maturation has evolved significantly. Today, dry maturation cabinets allow restaurants, butchers and speciality shops to mature meat in a safe and controlled manner.

Dry maturation involves hanging the meat in a controlled environment, which allows flavours to concentrate and textures to become more tender.

Wet maturation, on the other hand, is carried out by vacuum-packing the meat, which retains moisture but does not offer the same depth of flavour and tenderness as dry maturation.

Meat maturation improves the tenderness and flavour of the final product. In addition, Coreco's Master Ageing Controller technology ensures precise control of essential parameters, resulting in high quality meat that meets the expectations of the most demanding consumers.

Dry-aged meat offers an unparalleled flavour and texture, characteristics that are highly valued by chefs and meat enthusiasts. In addition, the artisanal process and the time invested in dry maturation add premium value to the product, making it highly sought after in restaurants and speciality shops.

Coreco Gourmet: Solutions for good meat maturation

Find out more about our advanced meat maturation solutions and how they can improve the quality of your products, download our catalogue and discover all that Coreco has to offer. You can also contact our sales team for personalised advice.

We hope this article has provided you with a detailed and useful insight into the process and evolution of meat maturation, as well as the advantages of using our specialised cabinets.

At Coreco, we are committed to quality and innovation and would be delighted to be your reliable partner. Thank you for joining us on this occasion and we look forward to seeing you in future publications.